Buy and manage subscriptions, distribute seats for your team members, control subscription status (current number of seats and expiration date) right in the app.

Lean Management

What is the Lean management system?

Lean management is a popular approach to running a company based on the concept of continuous improvement. In other words, it is an ongoing effort to refine products, services, or processes, which require “incremental” improvement over time in order to increase efficiency and quality.

The main purpose of lean management is to reduce factors that waste time, effort or money. The only way to manage it is to analyze a business process and then revise it and cut out every step that does not create value for customers.

Want to try Kanbanchi?

Lean Principles

Lean management principles include:

- Defining value from the standpoint of the end customer.

- Identifying each step in a business process and eliminating those steps that do not create value.

- Making the value-creating steps occur in a tight sequence.

- Repeating the first three steps on a continuous basis until all waste has been eliminated.

These principles of lean management ensure that production and market launch remain cost-effective.

Lean manufacturing or production is a systematic method for the elimination of wastes within a production process. For instance, waste can be caused by unevenness in workloads, overburden, or any work that does not add value. From a customer’s point of view, “value” is any process or action that he would be willing to pay for. Basically, the lean management system is focused on making obvious what brings value by decreasing everything else.

History of Lean Production system

Сertainly, the waste reduction has a long history within the manufacturing industry. In fact, lean principles and key concepts have been discovered and rediscovered several times over the years. People were looking for ways to avoid waste. But lean production, as a management philosophy, came mostly from the Toyota Production System (TPS).

It was John Krafcik who introduced the term “lean” in the article “Triumph of the Lean Production System” in 1988. He wrote the article on the basis of his master’s thesis at the MIT Sloan School of Management. Before his studies, Krafcik had worked as a quality engineer in the Toyota-GM NUMMI.

The other important figure was Kiichiro Toyoda. He was the founder of Toyota Motor Corporation. While he directed the engine casting work he found many problems in their production process. He created the “Kaizen” improvement teams when his processes faced new problems in 1936. Toyota states that the main aspect of lean methodology is not the tools, but the reduction of three types of waste:

- muda (“non-value-adding work”)

- muri (“overburden”)

- mura (“unevenness”)

This aids in exposing problems systematically and makes it easier to use the right tools where the ideal cannot be achieved. Taiichi Ohno, a Japanese industrial engineer, and businessman is considered to be the father of the Toyota Production System. He offered to focus on the reduction of the original Toyota seven wastes to improve the end product.

The Lean Management Tools

Many elements within the concept of lean production stand out and each of these presents a particular method:

- 5S

- Kanban (pull systems)

- Value Stream Mapping

- SMED

- Poka-yoke (error-proofing)

- Elimination of Time Batching

- Total Productive Maintenance

- Mixed Model Processing

- Single Point Scheduling

- Rank Order Clustering

- Multi-process Handling

- Redesigning Working Cells

- Control Charts (for checking mura)

Some of these methods, such as kaizen and kanban have grown into independent production concepts.

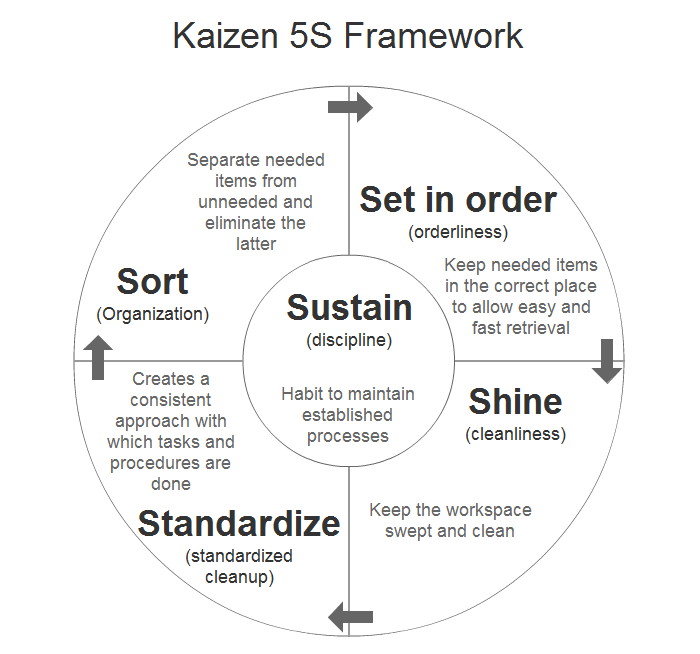

Kaizen 5S

5S is a perfect way to cope with waste and increase profitability. The letter “S” stands for 5 words: straighten, sort, standardize, shine, and sustain. Actually, it is a translation from original Japanese words: seiton, seiri, seiketsu, seiso, and shitsuke. These words describe ways for workspace organizations to achieve the most efficiency. For instance, identifying and storing the used items, maintaining the items and area, and sustaining the new order.

5S has become a fundamental business measure and a key driver for Kaizen. The 5 Steps are as follows:

- Sort: Sort out and separate what is needed and not needed within the area.

- Straighten: Arrange items that are needed so that they are ready and easy to use. Clearly identify a place for each of all items so that anyone can find them and return them once the task is completed.

- Shine: Clean the workplace and equipment on a regular basis in order to maintain standards and identify defects on time.

- Standardize: Revisit the first three of the 5S on a frequent basis and confirm the condition of the Gemba using standard procedures.

- Sustain: Keep to the rules in order to maintain the standard and continuously improve every day.

Kanban

Kanban’s visual management is one of the best ways to waste reduction. In 1952, Taiichi Ohno invented a kanban system at Toyota, as a system to improve and maintain a high level of production.

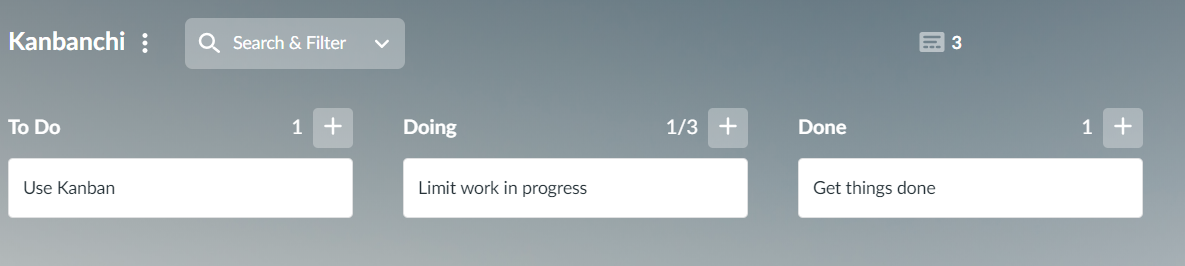

Later, Kanban became an effective tool to support production processes as a whole. In addition, it is an excellent way to promote continuous improvement. One of the main benefits of the kanban system is the opportunity to set up an upper limit to the work-in-progress inventory. It allows for avoiding overloading the system of production. Kanban’s concept of “to do” – “doing” – “done” became the cornerstone of many online tools used for managing projects and controlling workflows. Kanbanchi is one of those tools that support the Kanban algorithm. If you are interested, you may try it now and see how it will raise your productivity.

Taiichi Ohno stated that kanban must follow strict rules of use in order to be effective. Toyota, for example, has six simple rules. Close monitoring of these rules is a never-ending task. This ensures that the kanban system does what is required:

- A Later process picks up the number of items indicated by the kanban at the earlier one.

- The Earlier process produces items in the quantity and sequence indicated by the kanban.

- No items are made or transported without a kanban.

- Always attach a kanban to the goods.

- Defective products are not sent on to the subsequent process. The result is 100% defect-free goods.

- Reducing the number of kanbans increases sensitivity.

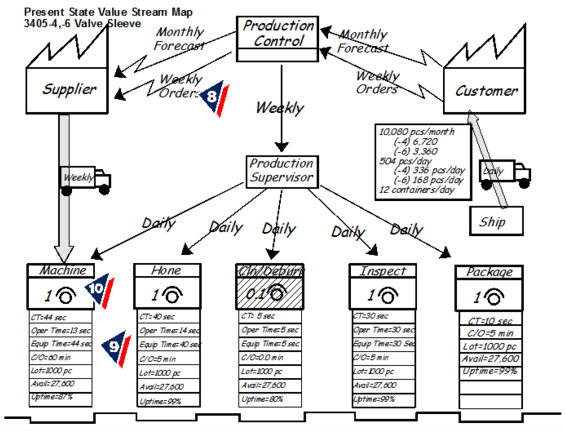

Value Stream Mapping

Value stream mapping is a method of lean management that is applicable to almost any value chain. It is used for analyzing the current stage and designing its further stages for the series of events that take a service or product from the beginning through to the client. This method is also applicable to:

- Logistics

- Supply Chain

- Service-Related Industries

- Healthcare

- Software Development

- Product Development

- Administrative or Work Processes

Value stream mapping usually employs standard symbols to represent items and processes. The best way to create a VSM is to draw with a pencil and on a sheet of A3 paper. The reason is that you will need to make a lot of frequent corrections and changes.

In fact, VSM is a relatively recent addition to the TPS toolbox. Even in the late 1990s, these techniques were for the most part unknown outside of Toyota. Later John Shook and Mike Rother co-authored the book “Learning to See”, published by the Lean Enterprise Institute. This is what made the material and information flow widely accessible for use outside of Toyota.

Certainly, value stream mapping is a flexible tool that lets us put all of the information into one place in a manner that is not possible with process mapping or other tools. Read this article to learn about creating a value stream map.

Six Sigma

Definitely, sigma is a mathematical term that measures a process deviation from perfection. Like Kaizen, Six Sigma is a management philosophy focused on making and bringing continuous improvement into various processes. Bill Smith first introduced the term in 1986 at Motorola.

Unlike Kaizen, which primary goal is increasing the efficiency of all aspects of processes, Six Sigma focuses on improving the quality of the final product by finding and eliminating causes of defects. Six Sigma uses statistical analyses and aims to reduce defects to zero. A sigma rating describes the maturity of a production process by indicating the percentage or yield of defect-free products it creates. Сompanies need to determine a proper sigma level for each of their most important processes and strive to achieve these.

The core tool used to drive Six Sigma projects is the DMAIC improvement cycle. DMAIC is an abbreviation of the five improvement steps it comprises: Define, Measure, Analyze, Improve, and Control. All of the steps are required and always proceed in the given order.

DMAIC refers to a data-driven improvement cycle used for improving, optimizing, and stabilizing business processes and designs. The five steps are not exclusive to Six Sigma. So they can serve as the framework for other improvement applications.

The Six Sigma concept asserts:

- Achieving sustained quality rise requires effort from the entire company, especially from top-level management.

- Production and business processes have features that can be measured, analyzed, controlled, and improved.

- Continuous efforts to achieve stable and predictable process results (i.e., reduce process variation) are of vital importance to business success.

- Apart from previous features, Six Sigma also sets the following quality improvement initiatives:

- A clear commitment to making decisions on the basis of verifiable data and statistical methods, rather than assumptions and guesswork.

- An increased emphasis on strong and passionate management leadership and support.

- A clear focus on achieving measurable and quantifiable financial returns from any Six Sigma project.

At the end of the 1990s, over 60% of companies with a Fortune 500 status started to apply Six Sigma. Thus, Motorola has declared about $17 billion in savings since 2006 as a direct result of implementing it.

In recent years became popular to use Six Sigma ideas combined with lean production. So, the Lean Six Sigma approach includes Six Sigma, with its focus on variation and design, and lean thinking, which addresses process flow and waste issues as extra disciplines aimed at promoting business and functional efficiency.