What is Kanban System?

Almost any productivity book, no matter whether it is about personal or professional life, will try to teach you how to get more things done in less time. It is a great goal, but it shouldn’t be the only one. How things are done is also important. If you don’t want to choose between quality and quantity Kanban system will show you how to combine them.

What is Kanban?

Kanban is a popular visual system great for managing work while it moves through the process. Kanban helps to visualize both the workflow and the current work passing through it. It gives an opportunity to identify potential bottlenecks in the process and arrange everything so that work can flow through them cost-effectively with an optimal capacity and speed.

The first Kanban system was developed in the 1940s by Taiichi Ohno. This prominent Japanese businessman created a Kanban planning system for his employer Toyota. The system was aimed to manage and control work and inventory at every production stage optimally. With this system, Toyota achieved a high level of production while integrating improvement in both methods and products. The overall goal of Kanban is to facilitate lean and just-in-time production. Another goal of Kanban is greater transparency in the manufacturing process.

Time passed and Kanban becomes an efficient way in a variety of production systems. Now it is often used in Marketing and Sales, Recruitment, Procurement, Staffing, IT/ Ops, software development, and etc. You may be sure – using this planning system will bring gradual improvements to whatever you do. Almost any business and business function can benefit from utilization of the Kanban Concept.

The Concept

Kanban is an evolutionary, non-disruptive method. It means that you keep using the existing process and improve it in small steps. Implementing many small changes (rather than a sizeable one) reduces the risk to all the system. The evolutionary approach of the Kanban method helps to low or nullify resistance in the team and the involved stakeholders.

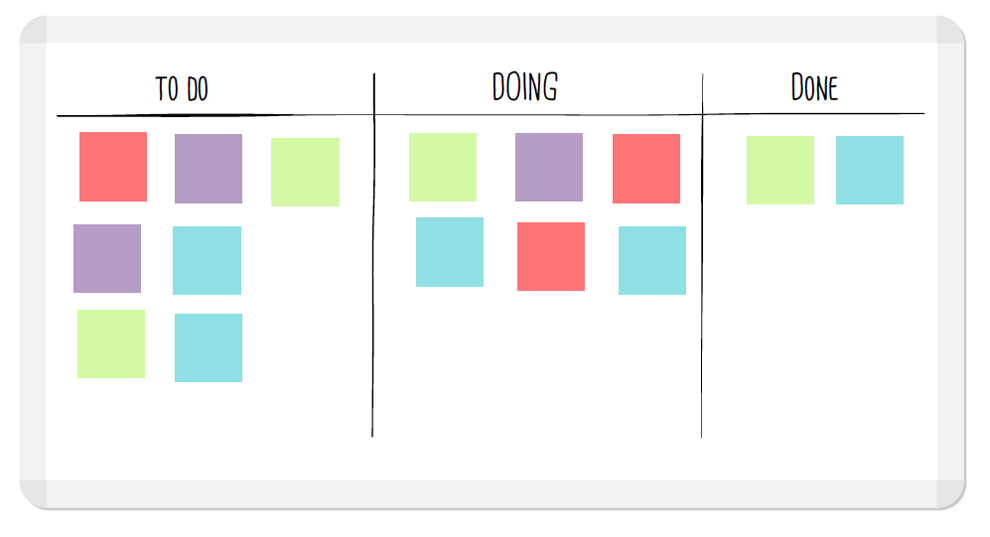

The first step you should do to implement the Kanban system is to visualize your workflow. This should be done in the form of a Kanban board what means just a simple whiteboard with cards or sticky notes for tasks. The whole method was named after this board because “Kanban” is translated from Japanese as “signboard” or “billboard”. The classic Kanban board model has three columns: “To Do”, “Doing”, “Done”.

This simple visualization alone gives a great deal of transparency regarding the work distribution as well as potential bottlenecks if any. Of course, Kanban boards can show much more complicated and elaborate workflows if it is necessary.

Kanban Cards

When the work has started, the cards/tasks with single steps in the production process should be moved from the “To Do” column to the “Doing” column. When a process has been completed the card indicating it is moved to the “Done” column.

To get the best results you should make sure that the cards flow through your system as evenly as possible, without prolonged waiting or blockages. Everything that interferes with the flow needs to be critically examined and improved. It will help you to dramatically speed up your delivery processes while reducing cycle time and improving the quality of your products or services by getting faster feedback from your customers.

WIP Limits

Also a very important aspect of Kanban is reducing of multi-tasking that the majority of teams and knowledge workers are prone to do. Instead of it the system encourage limiting Work-in-Progress (WIP). Limits defined at each stage of the workflow on a board will make team members finish work at hand and only then, take up the next piece of work.

Kanban Online

Nowadays Kanban cards and dashboards of any kind are incredibly popular. Over the years, the system has taken on other variances which make it more suitable for different organizations. For example, a growing number of companies have created online Kanban systems, which help to track steps in the process without paper cards and physical boards. Kanbanchi supports the Kanban system and makes it easily accessible online.