In this Article:

Try Kanbanchi now

Start your free trial

Auto repair shops face complex operational challenges every day. Multiple vehicles in different repair stages, technician coordination across service bays, parts delays, and customer communication demands create a perfect storm of complexity. Kanbanchi brings visual project management to automotive service centers, transforming how shops track repairs, schedule technicians, and manage parts inventory. This case study explores how auto repair shops use this auto repair project management software to streamline operations, reduce turnaround times, and improve customer satisfaction through proven workflows that deliver measurable results.

Modern auto repair shops operate under intense pressure. Service advisors juggle phone calls, walk-in customers, and insurance adjusters while coordinating with technicians working on multiple vehicles simultaneously. Each vehicle represents a unique combination of diagnostic work, repair procedures, parts requirements, and customer expectations.

Technicians face their own challenges. Paperwork orders get lost or damaged in busy shop environments. Whiteboard systems show current status but fail to capture detailed repair histories or document completed steps. Communication breakdowns occur when information stays trapped in one person’s head rather than being documented in accessible systems.

Parts delays create cascading problems throughout the shop. A technician waiting for a brake caliper sits idle while other vehicles queue up behind the stalled repair. Service advisors struggle to provide accurate completion estimates to customers when parts availability remains uncertain.

Customer communication adds another layer of complexity. Shops must balance proactive updates with staff productivity, ensuring customers stay informed without overwhelming technicians with constant interruptions. Missed communications lead to frustrated customers and negative reviews that damage the shop’s reputation.

Precision Auto Service operates as an independent repair facility serving both retail customers and commercial fleet accounts. The shop employs eight technicians across six service bays, handling everything from routine maintenance to complex diagnostics and major repairs.

The business serves a diverse customer base. Retail customers bring vehicles for oil changes, brake service, and general repairs. Fleet accounts require scheduled maintenance, quick turnarounds, and detailed documentation for their records. The shop also partners with local dealerships for overflow work and specialty repairs.

Service offerings span the full spectrum of automotive repair. Preventive maintenance includes oil changes, tire rotations, and fluid services. Diagnostic work ranges from check engine lights to electrical system troubleshooting. Major repairs include engine and transmission work, suspension overhauls, and collision-related mechanical maintenance.

The team structure reflects the shop’s operational needs. The shop manager oversees daily operations and handles vendor relationships. Two service advisors manage customer interactions and coordinate workflow with technicians. Eight technicians bring specialized skills in diagnostics, electrical work, and mechanical repairs. A parts coordinator manages inventory and vendor orders.

Precision Auto evaluated multiple solutions before selecting its garage workflow management system. Generic project management tools lacked automotive-specific terminology and workflow patterns. Automotive-specific software packages were expensive to license and required extensive training.

The shop manager explained their selection criteria. “We needed something our technicians would actually use. Complex systems with steep learning curves don’t work when you have grease on your hands and five vehicles waiting”. Cost represented another critical factor for the independent shop operating on tight margins.

Kanbanchi emerged as the ideal compromise. The visual Kanban boards matched how technicians already think about workflow. Integration with Google Workspace meant no additional infrastructure costs since the shop already used Gmail and Google Drive. The intuitive interface required minimal training, allowing staff to become productive quickly.

The pricing structure made financial sense. At $5.99 per user per month, the shop could deploy Kanbanchi across the entire team for less than the cost of one automotive-specific software license. The free trial allowed hands-on evaluation before commitment.

Implementation began with a pilot program involving two service advisors and three technicians. The team created their first board structure during a Monday morning meeting, mapping out the repair workflow stages they needed to track.

The initial board included lists for New Work Orders, Awaiting Parts, In Progress, Quality Check, and Ready for Pickup. Each vehicle became a card containing customer information, required services, assigned technician, and current status. The team refined the structure based on daily feedback during the two-week pilot period.

Digital work order conversion happened gradually. Service advisors created cards as vehicles arrived, capturing all relevant information in the card description. They attached photos from Google Drive showing vehicle condition and damage. Estimated completion dates and customer contact preferences went into custom fields.

Technician assignment systems evolved through practice. Service advisors initially assigned cards based on technician specialties. The team later added assignment categories for diagnostic work, general repairs, and specialty services. Technicians could see their assigned work through Kanbanchi’s “My tasks” feature, which aggregated all their assignments across different boards.

Parts ordering workflows are integrated into the card system. When technicians identified the needed parts, they added comments to the cards with the part numbers and vendors. The parts coordinator monitored these comments and placed orders accordingly. Cards were moved to the Awaiting Parts list until components arrived.

Visual boards revolutionized shop floor visibility. Service advisors and technicians could see every vehicle’s status at a glance. Color-code differentiated work types: red for diagnostics, blue for routine maintenance, and green for significant repairs. This visual system eliminated the need for constant status updates and check-ins.

The Kanban board structure supports unlimited cards and customizable workflows. Precision Auto created separate boards for retail customers, fleet accounts, and warranty work. Each board followed a similar workflow stage but included custom fields relevant to that customer type.

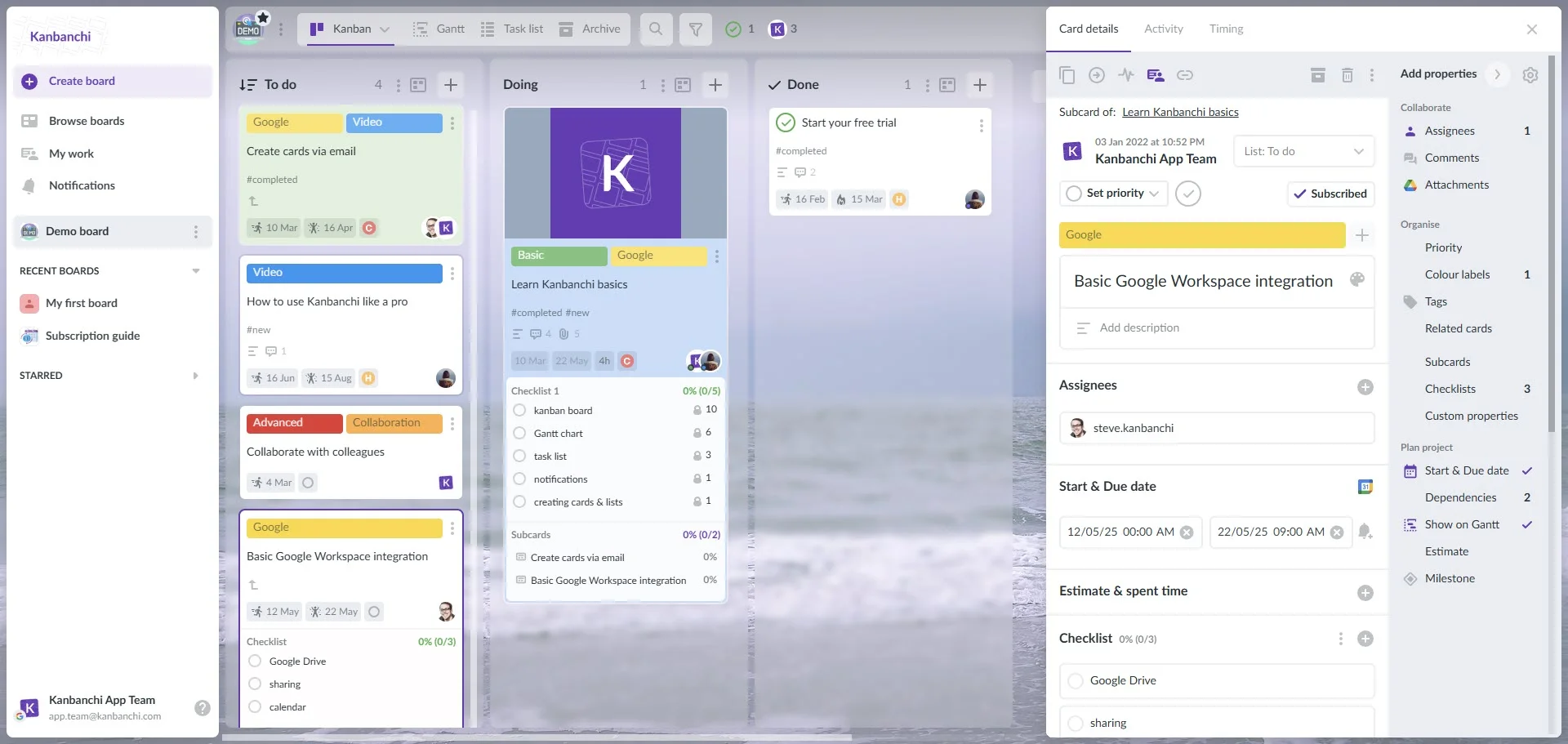

Example of the Kanbanchi interface showcasing a Kanban board used with the Google account

Vehicle status tracking happened automatically as cards moved between lists. When a technician started work on a vehicle, they moved its card to In Progress. The timestamp on this move was automatically recorded when work began. Moving cards to Quality Check triggered notifications to service advisors that vehicles needed inspection before customer pickup.

Technician assignment cards were displayed clearly on the board. Each card displayed the assigned technician names, making the workload distribution visible to everyone. Service advisors could quickly identify which technicians had capacity for new work and which were fully booked.

Mobile access proved essential for shop floor work. Technicians accessed Kanbanchi on tablets and smartphones, updating cards without returning to the office computer. They could start time trackers, add comments, and move cards between lists from anywhere in the shop.

The integrated time tracker provided accurate labor tracking. Technicians clicked the start button when beginning work on a vehicle and stopped it upon completion. Time logs automatically appeared in card comments with timestamps. This data is fed to billing systems and productivity analysis.

Parts tracking is integrated seamlessly into card workflows. Comments documenting parts orders remained visible to everyone involved. Attachments from Google Drive included parts invoices and shipping confirmations. When the parts arrived, the parts coordinator moved the cards from Awaiting Parts back to In Progress.

Google Calendar integration synchronized essential deadlines. Promised completion dates appeared on both Kanbanchi cards and technician calendars. Service advisors could see technician availability when scheduling new work. This integration prevented double-booking and ensured realistic customer commitments.

Vehicle turnaround times decreased significantly after implementation. Average repair completion time dropped from 3.2 days to 2.4 days, a 25% improvement. This reduction came from better workflow visibility and faster communication between team members.

Missed diagnostic steps declined dramatically. The checklist feature within cards ensured technicians completed all required procedures. Quality issues from skipped steps decreased by 40% in the first six months. This improvement reduced comebacks and enhanced customer satisfaction.

Parts ordering efficiency improved measurably. The average time between identifying needed parts and placing orders dropped from 4 hours to 45 minutes. Centralized communication through card comments eliminated the delays caused by tracking down the parts coordinator. Parts-related delays decreased by 35%.

Customer satisfaction scores increased substantially. Post-service surveys showed satisfaction ratings rising from 4.1 to 4.6 out of 5. Customers specifically mentioned appreciating proactive communication about repair status and accurate completion time estimates. Online review ratings improved from 3.8 to 4.4 stars.

Revenue per service bay increased by 18%. More efficient operations meant each bay could handle additional vehicles without increasing staff. The shop completed an average of 12 additional vehicles per week with the same team size.

The shop manager quantified the financial impact. “Our labor efficiency improved enough to offset the software cost within the first month. The real value comes from handling more vehicles without adding overhead”. Service advisors echoed this sentiment, noting they could manage larger workloads without feeling overwhelmed.

| Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Average repair completion time | 3.2 days | 2.4 days | 25% reduction |

| Time between identifying parts and placing orders | 4 hours | 45 minutes | 81% reduction |

| Post-service satisfaction ratings | 4.1/5 | 4.6/5 | 12% increase |

| Online review ratings | 3.8 stars | 4.4 stars | 16% increase |

| Additional vehicles completed per week | 0 | 12 | 12 additional vehicles/week |

Lead technician Mike Rodriguez described the transformation. “I used to waste 20 minutes every morning figuring out what I was supposed to work on. Now I open my tasks on my tablet and see everything assigned to me in priority order”. This clarity eliminated confusion and allowed technicians to start productive work immediately.

Service advisor Sarah Chen highlighted improvements in communication. “Before Kanbanchi, I would walk around the shop three or four times per day asking for status updates. Now I just look at the board and see exactly where every vehicle stands”. This efficiency gave her more time for customer interactions and less time on internal coordination.

Parts coordinator James Wilson emphasized the importance of ordering efficiency. “I get notifications whenever someone adds a parts request to a card. I can place the order immediately instead of waiting until someone tracks me down”. The documented history of parts orders also helped resolve vendor disputes and track warranty claims.

Technician Maria Gonzales appreciated the mobile functionality. “I can update cards from the shop floor without getting oil on the office keyboard. I pull up the card on my phone, tap the time tracker to start, and get to work”. This convenience ensured accurate time tracking without disrupting workflow.

Shop manager Tom Anderson summarized the team perspective. “The biggest win is that everyone can see what everyone else is doing. There’s no more ‘I didn’t know that was my job’ or ‘I thought someone else was handling that'”. This transparency created accountability and reduced errors caused by communication breakdowns.

Board setup varies by shop size and service types. Small shops with fewer than five technicians often use a single board with color-coded cards for different service categories. Larger shops benefit from multiple boards segmented by customer type, such as retail, fleet, and commercial accounts.

The column structure should mirror the actual workflow stages. Most auto shops use variations of Intake, Diagnostic, Awaiting Parts, In Progress, Quality Check, and Ready for Pickup. Some shops add specialized columns for specific processes, such as tire work or alignment services.

Color coding creates instant visual clarity. Red cards typically indicate urgent work or vehicles promised for same-day completion. Yellow marks vehicles awaiting parts or customer authorization. Green shows routine maintenance that can flex around more urgent work. Blue indicates diagnostic work requiring focused technician attention.

Priority levels help service advisors manage workload. Kanbanchi’s priority feature lets you mark cards as low, medium, high, or critical. Lists can automatically sort by priority, ensuring urgent work stays visible at the top.

Checklist implementation standardizes procedures. Creating card templates with pre-populated checklists for standard services ensures consistent quality. An oil change template might include steps for oil drain, filter replacement, fluid top-off, and multi-point inspection. Technicians check off items as they complete them, creating documentation of work performed.

Customer communication templates maintain professionalism. Service advisors can save standard responses for common scenarios in card comments. Templates for parts delays, additional work needed, and completion notifications ensure consistent messaging.

Time tracking discipline requires management support. Shops achieve best results when management emphasizes accurate time logging and uses the data for productivity analysis rather than punishment. The time tracker data exports to Google Sheets for payroll integration and job costing analysis.

Bay utilization improvements drive significant financial returns. Precision Auto Service increased the number of vehicles completed per bay per week from 6.2 to 7.3, an 18% improvement. With average repair revenue of $450 per vehicle, each bay generated an additional $23,400 annually.

Reduced rework eliminates waste. Fewer missed diagnostic steps and better documentation decreased comeback rates by 40%. For a shop completing 50 vehicles per week, this prevented approximately four redo jobs per week. Each prevented rework saved 2-3 hours of technician time, plus the cost of customer dissatisfaction.

Parts inventory management became more efficient. Better communication reduced emergency parts orders requiring expedited shipping. The shop saved approximately $300 monthly in rush shipping charges. More accurate parts ordering also reduced inventory carrying costs by 15%.

Customer retention improved through better service quality. The increase in customer satisfaction scores translated to a 12% improvement in repeat customer rates. For a shop serving 200 customers monthly, this meant 24 additional returning customers generating repeat revenue.

Staff productivity gains reduced overtime requirements. Service advisors and technicians completed work during regular hours rather than staying late to catch up. Overtime pay decreased by approximately $1,200 monthly. This reduction improved work-life balance and reduced employee turnover.

The comprehensive financial analysis showed precise results. Initial software costs of $72 per month for 12 users generated documented savings and revenue increases exceeding $3,000 monthly. The payback period was under two weeks.

| Metric | Improvement |

|---|---|

| Vehicles completed per bay per week | 18% improvement |

| Additional annual revenue per bay | $23,400 annual increase |

| Comeback rates | 40% reduction |

| Prevented redo jobs per week (for 50 vehicles/week) | 4 fewer redo jobs weekly |

| Monthly rush shipping charges | $300 monthly savings |

| Inventory carrying costs | 15% reduction |

| Repeat customer rates | 12% improvement |

| Additional returning customers monthly (for 200 customers/month) | 24 additional returning customers monthly |

| Monthly overtime pay | $1,200 monthly decrease |

| Initial software costs (12 users) | $72/month for 12 users |

| Monthly savings and revenue increases | Exceeding $3,000 monthly |

| Payback period | Under two weeks |

Initial board structure development takes 1-2 hours. Gather service advisors and lead technicians to map current workflow stages onto Kanban columns. Start simple with 4-5 columns representing primary stages, then add complexity as the team gains experience.

Work order templates streamline card creation. Build templates for common service types, including oil changes, brake service, diagnostics, and major repairs. Include standard checklists, typical labor times, and common parts requirements. Service advisors can create new cards from templates in under 30 seconds.

Technician onboarding requires minimal training. The visual nature of Kanban boards makes the system intuitive. Schedule 15-minute one-on-one sessions showing technicians how to view assigned cards, start time trackers, and update status. Most technicians become proficient within their first day.

Parts tracking setup involves the parts coordinator and service advisors. Establish conventions for documenting parts requests in card comments. Create a standardized format that includes part numbers, vendors, and urgency levels. The parts coordinator can then monitor cards for parts requests and respond accordingly.

Mobile access configuration takes minutes. Technicians can access Kanbanchi through mobile browsers or install the web app on their devices. The interface adapts automatically to smaller screens while maintaining full functionality.

Google Drive integration happens automatically for Google Workspace users. Boards save as files in Google Drive, following the same sharing and permission rules as other documents. Service advisors can attach photos, invoices, and inspection reports from Google Drive directly to cards. Similarly, Kanbanchi operates within MyDrive or SharePoint in the Microsoft environment.

Calendar synchronization enables deadline tracking. Service advisors can push promised completion dates from cards to Google Calendar with one click. These dates appear on technician calendars, helping them manage their time and prioritize work.

Trial periods allow risk-free evaluation. Kanbanchi offers a 7-day free trial providing full access to all features. Shops can test the system with real work orders before making a financial commitment. The Essential plan starts at $5.99 per user monthly after the trial period.

Can Kanbanchi integrate with diagnostic tools? Kanbanchi primarily works in web browsers and doesn’t offer direct integration with automotive diagnostic equipment. However, shops can attach diagnostic reports saved as PDFs from Google Drive to vehicle cards. This provides documentation without requiring technical integration.

Does mobile access work for technicians on the shop floor? Yes, Kanbanchi works fully on mobile devices via a browser or as an installed web app. Technicians can view assigned cards, start time trackers, add comments, and update status from smartphones or tablets. The interface automatically adapts to mobile screens.

How does the time tracker integrate with payroll? The time tracker captures actual work time on each card with start and stop functionality. This data exports to Google Sheets for integration with payroll and accounting systems. The exported data includes employee names, dates, times, and card descriptions.

Can we set up customer-facing status updates? Kanbanchi doesn’t provide a native customer portal. However, service advisors can use card information to send manual updates via email or text. Some shops create shared view-only boards for commercial fleet customers who want direct visibility into their vehicles.

What happens to the data if we cancel? Kanbanchi boards store as files in Google Drive. If you cancel your subscription, boards become read-only but remain accessible in your Google Drive. You can export data to Google Sheets before canceling to maintain records.

How do we handle warranty work documentation? Create dedicated cards or boards for warranty repairs. Use the checklist feature to document required procedures matching warranty requirements. Attach photos and inspection reports from Google Drive as warranty documentation. Comments provide timestamped records of who performed each step.

Can multiple shops share boards? Yes, Kanbanchi boards can be shared with anyone who has the appropriate Google Drive permissions. Multi-location shops can create separate boards for each location or consolidated boards showing work across all facilities. Access control follows standard Google Drive sharing rules.

You will find more content related to managing operations here

Here are some of the other cases that you might want to check out:

How Store Managers Use Kanbanchi for Operations and Inventory Management

How a South Asian Logistics Firm Streamlined Operations using Kanbanchi as a Logistics Project Management Software

Auto repair shops face unique operational challenges requiring specialized solutions. Kanbanchi delivers automotive service task management through visual boards that match how repair shops actually work. The combination of intuitive design, powerful features, and affordable pricing makes it accessible to shops of all sizes.

Real-world results demonstrate the platform’s value. Precision Auto Service reduced vehicle turnaround time by 25%, improved customer satisfaction by 12%, and increased revenue per bay by 18%. These improvements came from better visibility, enhanced communication, and standardized procedures.

The path forward for interested shops starts with the free trial. Kanbanchi’s intuitive interface and minimal learning curve mean shops can evaluate the system with real work orders within days. The risk-free trial period allows for a hands-on assessment before making a financial commitment.

Integration with existing Google Workspace accounts eliminates infrastructure barriers. Shops already using Gmail and Google Drive can deploy Kanbanchi immediately without additional hardware or software. Mobile access ensures technicians can participate fully without leaving the shop floor.

Successful implementation requires management commitment and team involvement. Start with a pilot program involving key team members. Refine board structure based on daily feedback. Expand gradually as confidence grows. Maintain focus on solving actual workflow problems rather than perfect system design.

Project coordination for car repair shops becomes manageable with the right tools. Kanbanchi transforms chaotic operations into organized workflows that improve efficiency, reduce errors, and enhance customer satisfaction. The visual nature of the mechanic task tracking software makes the status instantly clear to everyone involved.

In this Article:

Start using Kanbanchi now

Start your free trial