In this Article:

Try Kanbanchi now

Start your free trial

Logistics in South Asia is a high-stakes balancing act. Monsoon rains disrupt routes, multi-language carrier networks create communication gaps, and e-commerce growth demands faster, more reliable deliveries – all while mid-size firms struggle to afford enterprise tools. For Siam Star Shipping, a medium-sized provider operating across Thailand, Vietnam, and Cambodia, these challenges were costing them 22% of freight shipments delayed, 15% of warehouse orders picked late, and 8+ hours weekly spent reconciling manual spreadsheets. This case study explores how Siam Star transformed its operations using Kanbanchi as logistics project management software.

Siam Star Shipping was founded in 2018 to fill a gap in South Asia’s logistics market: mid-size e-commerce brands needed reliable, affordable shipping across Thailand, Vietnam, and Cambodia without the price tag of enterprise firms like DHL or FedEx.

Size and Team: 85 employees across three offices (Bangkok HQ, Ho Chi Minh City satellite, Phnom Penh depot) and one Bangkok warehouse.

Roles include:

Services: Freight forwarding (sea/land), last-mile delivery, warehouse storage, and customs clearance, specializing in e-commerce (60% of clients) and FMCG (fast-moving consumer goods, 40% of clients).

Regional Focus: Thailand (70% of business), Vietnam (20%), Cambodia (10%). Plans to expand to Malaysia in 2026.

Unique Challenges: Monsoon seasons (June-October) disrupting land routes, multi-language carrier networks, varying customs regulations (e.g., Vietnam requires additional import docs for electronics), and spotty internet in rural areas.

By 2024, their client base had grown 40%, but their manual processes couldn’t keep up. “We were turning down clients because we couldn’t guarantee on-time deliveries,” said their founder. “We needed logistics project management software that could handle South Asia’s chaos. I tried a lot of tools built for Western markets, but we needed something we could customize.”

Before Kanbanchi, Siam Star workflows were held together by Excel spreadsheets, WhatsApp messages, and paper delivery notes. Systems that collapsed under the pressure of South Asia’s logistics. Here’s how their most significant pain points played out daily.

Siam Star Shipping works with 28 local carriers (trucking, sea freight, and last-mile delivery) across three countries. Each has different languages (Thai, Vietnamese, Khmer), schedules, and reliability. Without centralized freight coordination project management, shipments fell through the cracks. During Thailand’s 2024 monsoon season:

Carrier coordinator Nok Sinthu recalled: “I used to spend four hours daily calling carriers to check statuses. Half the time, they didn’t answer, or I couldn’t explain the issue in their language. By the time we resolved it, the client was angry.”

Siam Star Shipping’s Bangkok warehouse, which serves 12 e-commerce clients, used paper checklists for order picking, packing, and inventory management. As a result, 15% of orders were picked late, and 8% had missing items. During peak season (November-December 2024):

Warehouse supervisor Arun Thongdee said, “We could have five staff working on the same order because the checklist didn’t assign tasks. It was chaos, especially when we had more than a hundred orders a day.”

Customs and shipping documents (invoices, packing lists, import permits) were stored in three places: email attachments, a shared Google Drive folder, and physical files. When a carrier needed a permit for a Vietnam-bound shipment, Siam Star Shipping staff could spend hours searching for the document. That could delay the truck’s departure by 2-3 hours.

Operations manager Sudpawana Kosasang summed it up: “We didn’t have a single source of truth. Every process relied on someone remembering where a file was or who to call. For logistics, that’s a disaster.”

Siam Star spent three months testing three top options: SAP Logistics (enterprise), Blue Yonder (warehouse-focused), and Kanbanchi. They scored each tool on four logistics-critical criteria:

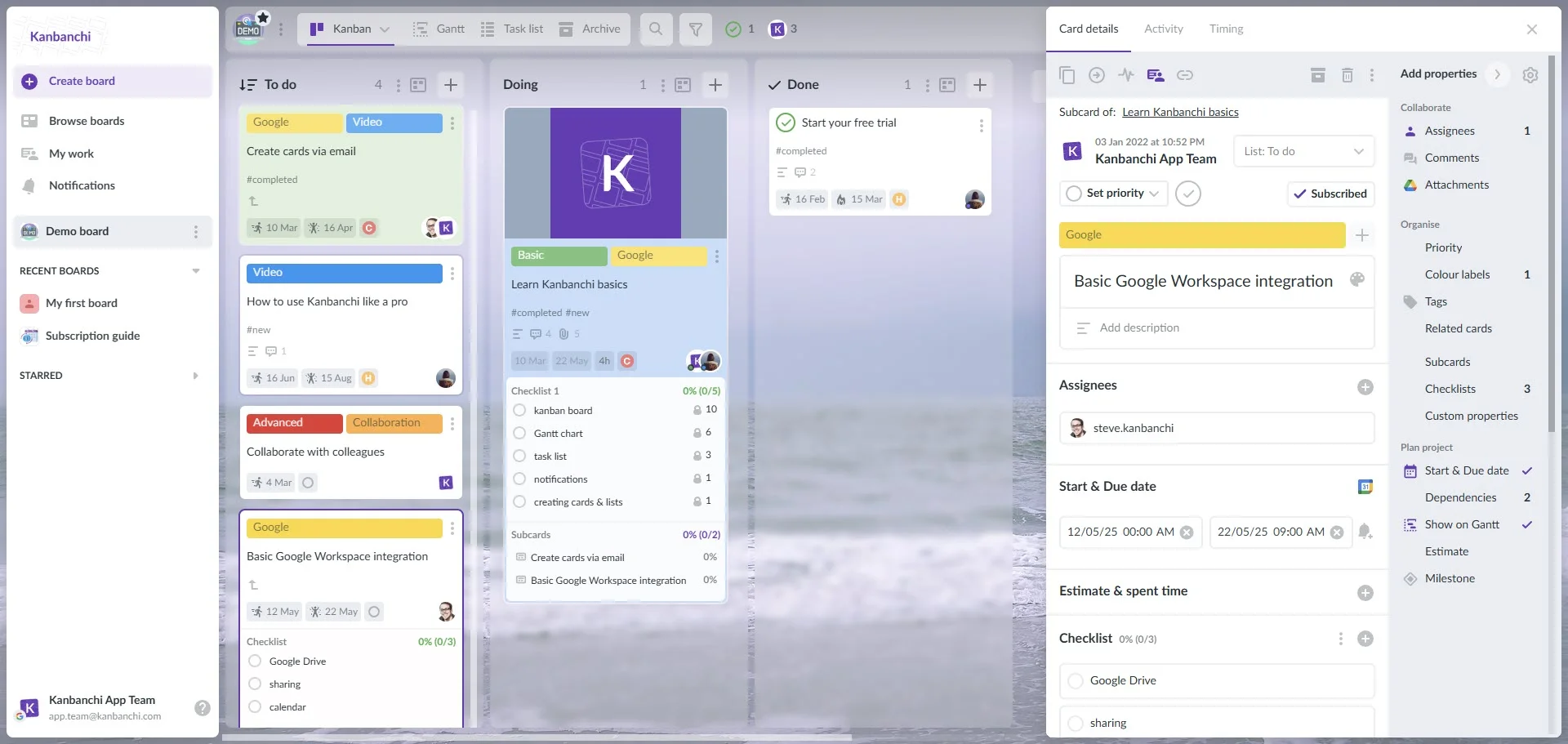

Kanbanchi interface showcasing the Kanban board

Here’s why Kanbanchi won:

SAP is a leader in enterprise logistics, but it was overkill for Siam Star Shipping.

What worked: Robust freight tracking and customs integration.

What failed: The interface required hours of training, and warehouse staff and drivers couldn’t navigate it. It also costs 650 per user/month (55,250 monthly for 85 staff), which was nearly 15% of Siam Star’s revenue.

Dealbreaker: No mobile app, useless for drivers and warehouse workers.

Blue Yonder excels at warehouse management, but it ignored Siam Star’s biggest pain: freight coordination.

What worked: Streamlined order picking and inventory tracking.

What failed: No way to track carrier shipments or optimize driver routes.

Dealbreaker: No Google Workspace integration. They all use Gmail for carrier communication and Google Drive for docs, so staff would have to switch between tools.

Kanbanchi checked every box and solved South Asia-specific challenges:

Ease of use: Drivers and warehouse staff learned the mobile app in 15 minutes. The visual boards (like physical checklists, but digital) felt familiar to non-technical teams.

End-to-end visibility: One platform for freight coordination, project management, warehouse operations, task tracking, and transportation task management tools. No more switching between spreadsheets.

Affordability: Kanbanchi’s Premium Plan costs $16.99 per user/month, and the Professional Plan $41.99 per user/month, and the price even goes down when you have more users. So, having separate plans for their different staff levels brought the cost down to $1995.65 per month for 85 staff. 28x cheaper than SAP!

Mobile app: Drivers can update delivery statuses in real-time.

Google Workspace integration: Customs documents stored in Google Drive attach directly to freight cards. Carriers can access them with one click, no more emailing files.

“We didn’t need a tool that did a thousand things; we just needed one that did four things really well: track freight, manage warehouses, share documents, and work on mobile. Kanbanchi delivered that,” summarizes the founder of Siam Star Shipping.

Siam Star Shipping knew a rushed rollout would fail, especially with staff across three countries and varying tech skills. They used a 6-week phased plan, focused on “regional relevance” (e.g., monsoon-specific features) and “role-specific training” (drivers learned mobile app; managers learned Gantt charts).

The HQ team (Sudpawana, Nok, Arun) worked with Kanbanchi support to create four core boards tailored to their unique workflows:

Columns:

Crucial properties:

Columns:

Crucial properties:

Columns:

Crucial properties:

Columns:

The archiving option became a significant bonus for the HQ team working with the documents, because archiving unnecessary cards sped up their active board and, at the same time, left space for the papers they might need to find quickly during various checks.

15 managers and coordinators were trained in Bangkok, Ho Chi Minh, and Phnom Penh on advanced features focused on solving their daily pain points:

The team created a “Regional Trainer Kit” with:

Training for drivers, warehouse staff, and carriers focused on the basic, actionable steps.

Drivers trained on the mobile app to:

Driver Phra said, “I used to carry a notebook with delivery addresses. Now I open the app, and the route is there.”

Warehouse staff were trained to:

Carriers (given a simplified link to the card) were trained to:

Siam Star Shipping collected feedback from its staff and made some adjustments. For example, added a “Monsoon Reroute” column to the Transportation Board: Drivers can flag routes with floods, and managers reassign stops in 5 minutes. In six weeks, 92% of staff were using Kanbanchi daily, exceeding their 85% goal.

Kanbanchi’s success at Siam Star wasn’t just about “using a tool”; it was about using features that solved South Asia’s logistics pain points. Below are the tools that made the most significant impact:

The Warehouse Operations Board replaced paper checklists, letting staff see task ownership and progress in real time. For example:

Arun said, “We used to have two staff working on the same order because no one knew who was assigned. Now, every task has a name. Picking time dropped from 4 hours to 2.9 hours per 100 orders.”

The shipment arrived on time. “Gantt charts turned reacting to delays into preventing them,” Nok said.

The mobile app and route optimization transformed driver workflows. Driver Phra’s daily route used to take 8 hours; now it takes 6.

Fuel costs dropped from 800 THB/week per driver to 624 THB/week, saving Siam Star 45,600 THB annually across 25 drivers.

Customs documents critical in South Asia are now attached directly to freight cards. When a carrier needs a Vietnamese import permit:

Sudpawana said, “We used to spend two hours per shipment finding docs. Now it’s five minutes. For 50 shipments a week, that’s hours saved. Time we use to serve more clients.”

The “Weather Alert” labels and “Carrier Language” tags solved two of Siam Star’s biggest regional challenges:

Siam Star’s founder said, “Enterprise tools don’t care about monsoons or multi-language carriers. Kanbanchi let us build those needs into the system, something no other tool offered us.”

TRY KANBANCHI FOR YOUR TEAM NOW

Siam Star tracked eight key metrics for 6 months after launching Kanbanchi, with results that transformed their bottom line and client satisfaction:

| Metric | Before Kanbanchi | After Kanbanchi | Improvement |

|---|---|---|---|

| Freight Delivery Delay Rate | 22% | 14.3% | -35% |

| Warehouse Order Picking Time (per 100 orders) | 4 hrs | 2.9 hrs | -28% |

| Fuel Costs (per driver/week) | THB 800 | THB 624 | -22% |

| Customs Doc Retrieval Time (per shipment) | 2 hrs | 0.6 hrs | -70% |

| On-Time Last-Mile Deliveries | 82% | 95% | +16% |

| Inventory Stockout Rate | 12% | 5% | -58% |

| Client Complaint Rate | 18% | 6% | -67% |

| Time Spent on Carrier Check-Ins (weekly) | 28 hrs | 8 hrs | -71% |

Cost Savings:

Sudpawana said, “We used to be known for delays. Now, clients call us the reliable ones. We turned our biggest weaknesses into strengths.”

Kanbanchi’s impact wasn’t just about numbers; it changed how Siam Star’s team worked and how they felt about their jobs. Here’s what they had to say:

Nok Sinthu, Carrier Coordinator (Bangkok): “Before Kanbanchi, I’d cry on my way to work because I knew I’d spend all day chasing carriers. Now I log in, see which shipments need updates, and send a quick message. No more endless calls. Last week, a carrier marked a shipment ‘Delayed’ at 9 AM, and I had a backup carrier assigned by 9:15 AM. The client never even knew there was a problem. That’s never happened before.”

Arun Thongdee, Warehouse Supervisor (Bangkok): “The warehouse used to be loud: staff arguing over who was picking what, clients calling to ask about orders. Now it’s quiet. Everyone has a task on the board and knows what to do. Last month, we processed 1,200 orders in 3 days (peak season) with no overtime. That’s a miracle for us.”

Phra Sorn, Driver (Thailand): “I’ve been a driver for 10 years, and I’ve never used a tool that makes my job easier. The app tells me where to go, in what order, and even lets me mark deliveries as soon as I complete them. I used to get home at 8 PM. Now I’m home by 6 PM to see my kids. That’s worth more than any raise.”

Mai Nguyen, Carrier Coordinator (Ho Chi Minh City): “Vietnamese carriers often don’t speak English, so miscommunication was a daily problem. Now the Freight Board has Vietnamese labels, and I assign Vietnamese-speaking staff to those carriers. Last week, a carrier needed a customs permit. They clicked the link on the board and had it in 2 minutes. No more ‘lost in translation’ issues.”

Founder of Siam Star Shipping: “We started Siam Star Shipping because we wanted to show that mid-size logistics firms in South Asia could compete with big players. Kanbanchi made that possible. We’re growing. Next year, we’re expanding to Malaysia, and I have zero doubt Kanbanchi will scale with us.”

Yes. Siam Star Shipping tracks 28 carriers across Thailand, Vietnam, and Cambodia using the Freight Coordination Board. The card properties for “Carrier Name,” “Country,” and “Doc Status” let you monitor every step from warehouse pickup to final delivery. You can filter by carrier, country, or status to spot bottlenecks.

Absolutely. The app lets drivers see routes, mark deliveries, and flag delays.

While Kanbanchi doesn’t integrate directly with customs platforms (e.g., Thailand’s Customs Department portal), it integrates seamlessly with Google Drive or SharePoint, where most logistics firms store customs documents. Carriers and staff can access them via attachment on the Kanbanchi card.

Most of the mid-size businesses use a mix of the Professional and Premium plans. Prices are customized and decrease as you add more users, starting at two users. You can check for yourself on our pricing page, which works as a calculator.

Yes. The Warehouse Operations Board’s “Inventory Location” label lets staff track stock by bin number, and the “Stockout” label alerts managers when items are low. Siam Star Shipping reduced inventory stockouts by 58% using this feature. Critical for e-commerce clients who can’t afford delays.

Ready to replicate Siam Star’s success? Follow these five steps to launch Kanbanchi as your logistics project management software.

Siam Star Shipping added these tweaks after three weeks and saw a 20% improvement in on-time deliveries.

You will find more content related to managing operations here

Here are some of the other cases that you might want to check out:

How Store Managers Use Kanbanchi for Operations and Inventory Management

Kanbanchi as the Catering Project Management Software for Event and Operations Management

Siam Star’s journey proves that mid-size logistics firms in South Asia don’t need enterprise tools to compete. They need logistics project management software that addresses their unique challenges: monsoons, multilingual carriers, and complex customs. Kanbanchi gave them the confidence to grow.

Today, Siam Star Shipping is expanding into Malaysia and using Kanbanchi to train new teams. “We don’t have to reinvent the wheel,” the founder says. “The boards work, the mobile app works, and the team knows how to use it. Kanbanchi turned our chaos into control.”

If you’re tired of manual processes holding your logistics firm back, whether you operate in Thailand, Vietnam, or beyond, Kanbanchi is the tool you need.

START YOUR FREE TRIAL OF KANBANCHI NOW

Build your first freight coordination board, and see how visual workflows can turn delays into on-time deliveries.

In this Article:

Start using Kanbanchi now

Start your free trial